Spining Yarn

Spinning yarn involves transforming raw fibers, like cotton or polyester, into continuous strands for weaving or knitting. The process starts with cleaning and carding the fibers to align them, forming a sliver. This sliver is drawn out and twisted using spinning wheels or industrial machines, giving the yarn strength and coherence. Additional processes, like plying, can combine multiple strands. The resulting yarn is essential for creating various fabrics used in clothing and other textiles.

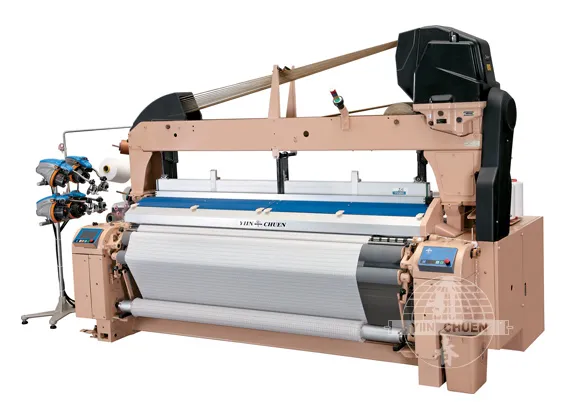

Jet Looms

Jet looms are advanced weaving machines that use high-speed air or water jets to propel the weft yarn through the warp threads. This technology allows for faster and more efficient weaving compared to traditional shuttle looms. Air jet looms use a burst of compressed air, while water jet looms utilize a stream of water to carry the yarn across the loom. These looms are highly efficient and capable of producing a wide range of fabrics with different textures and densities. Jet looms are particularly favored for their speed, precision, and the ability to handle a variety of yarn types, making them a popular choice in modern textile manufacturing.

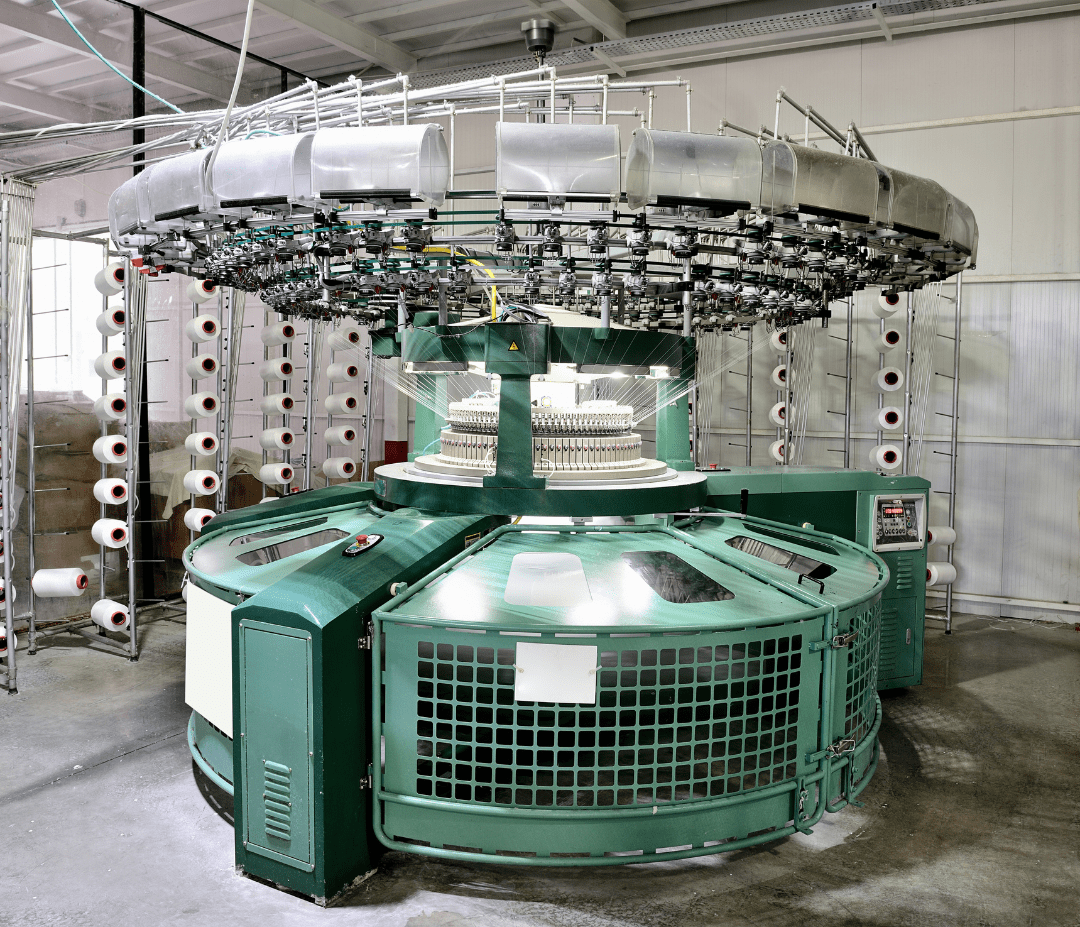

Kniting Machine

A knitting machine is a device that automates the process of knitting, significantly increasing speed and consistency compared to hand knitting. These machines range from simple, manually operated models to advanced, computerized versions capable of intricate patterns and designs. Knitting machines come in two main types: flatbed, which produces flat fabric pieces, and circular, which creates tubular fabrics ideal for seamless garments. They can handle various yarn weights and gauges, making them versatile tools for producing everything from garments and accessories to home decor. While the learning curve can be steep and the initial investment significant, the efficiency, consistency, and creative possibilities they offer make knitting machines a valuable asset for both hobbyists and professional knitters.

Flatbed Knitting Machines

Flatbed knitting machines have a flat, horizontal needle bed where needles are arranged in a straight line. They are versatile and can produce a wide range of flat knitted fabrics, which can then be sewn together to create garments and other items. Flatbed machines are often used for:

- Operated by hand, these machines require the user to move the carriage back and forth manually to knit each row. They are suitable for beginners and those who prefer more control over the knitting process.

- Equipped with computerized controls, these machines automate much of the knitting process, allowing for complex patterns and designs with minimal manual intervention. They are ideal for advanced users and professionals.

Circular Knitting Machines

- These machines knit one layer of fabric at a time, making them suitable for lightweight garments and accessories.

- Capable of knitting two layers simultaneously, these machines are ideal for creating thicker, double-layered fabrics and more complex structures like ribbing.

Bleaching Machine

A bleaching machine is an essential piece of equipment in the textile industry, used to whiten and purify fabrics by removing natural color, impurities, and stains. The process involves treating the fabric with bleaching agents, such as hydrogen peroxide or sodium hypochlorite, under controlled conditions of temperature and time. Modern bleaching machines are designed to handle large volumes of fabric efficiently, ensuring uniform treatment and minimal environmental impact. They often include automated systems for precise chemical dosing and advanced features to recycle water and chemicals, enhancing both productivity and sustainability in textile processing.

Printing

Printing, in a broad sense, refers to the process of reproducing text, images, or designs onto various surfaces, including paper, fabric, plastic, and more. It involves transferring ink or pigment onto the substrate using a variety of techniques, each tailored to specific materials and applications. Printing plays a crucial role in communication, advertising, art, and manufacturing, enabling the mass production of books, newspapers, packaging, signage, clothing, and other products. From traditional methods like offset and screen printing to modern digital technologies, such as inkjet and 3D printing, the field of printing continues to evolve, offering ever-increasing possibilities for creativity, efficiency, and customization.

Routery Machine

Allah Hoo Export specializes in premium textile dyeing services, delivering vibrant and long-lasting colors tailored to meet your specific needs. Our state-of-the-art facilities, coupled with a team of experienced professionals, ensure the highest quality standards in every project we undertake. We utilize advanced dyeing techniques and cutting-edge technology to achieve consistent and brilliant hues across various types of fabrics.

Choose Allah Hoo Export for your textile dyeing needs and experience the perfect blend of quality, innovation, and sustainability. With our expertise and dedication, we transform your fabrics into masterpieces of color and vibrancy, tailored to your exact specifications.

Cutting

A cutting machine is a versatile tool used in various industries to precisely cut materials like paper, fabric, vinyl, and cardboard. Types include die-cutting, laser cutting, CNC routers, and vinyl cutting machines. Die-cutting machines use metal dies, while laser cutting machines employ high-powered lasers for intricate designs. CNC routers are computer-controlled for accuracy in woodworking and metalworking, and vinyl cutting machines are specialized for creating decals and signage. Whether for hobbyists or industrial use, cutting machines offer efficiency and precision in material processing.

Stiching

Stitching is a fundamental technique in the textile and garment industry, involving the joining of fabrics, leather, or other materials using a needle and thread. This method creates seams, hems, and intricate patterns, contributing to the durability and aesthetic appeal of a wide range of products, from clothing and accessories to upholstery and home textiles. Various stitching techniques, such as running stitch, backstitch, and cross-stitch, offer different functional and decorative purposes. Modern stitching can be performed by hand or with the aid of sewing machines, each providing distinct advantages in terms of precision, speed, and complexity. Beyond its practical applications, stitching is also a form of artistic expression, allowing for the creation of detailed embroidery and bespoke designs that reflect cultural traditions and individual creativity.

Finishing

Finishing is the final stage of production where products undergo treatments or processes to enhance their appearance, functionality, and durability. This may involve painting, coating, polishing, dyeing, printing, or other treatments tailored to the specific industry. In manufacturing, textiles, and woodworking, finishing adds value and ensures products meet quality standards and customer expectations.

Final Packaging

Final packaging is the last step in production, involving careful selection of packaging materials, securing products within, labeling, and adding protective elements. It ensures products are safely delivered to consumers while conveying essential information and brand identity.

Delivery

Allah Hoo Export is known for its efficient and reliable delivery services, ensuring prompt and secure shipment of products both domestically and internationally. Utilizing a robust logistics network and advanced tracking systems, the company provides real-time updates and maintains transparency throughout the process. Their high standards of packaging ensure product safety, making Allah Hoo Export a trusted partner in global trade.